High Corrosion Resistance 6Mo Pipes for Chemical and Petrochemical Industries

Get Quote

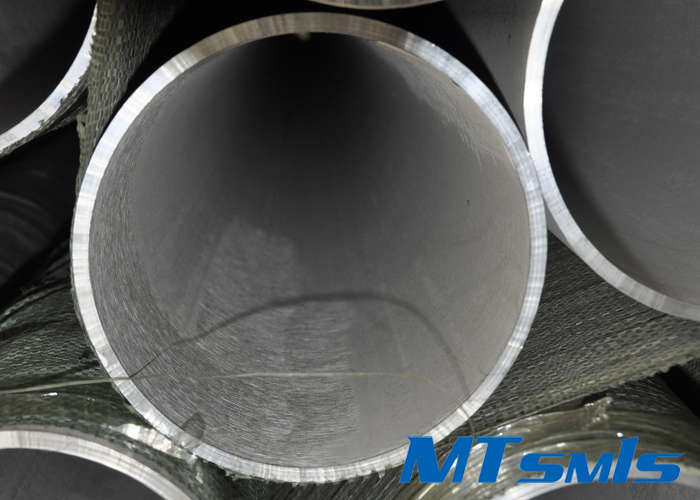

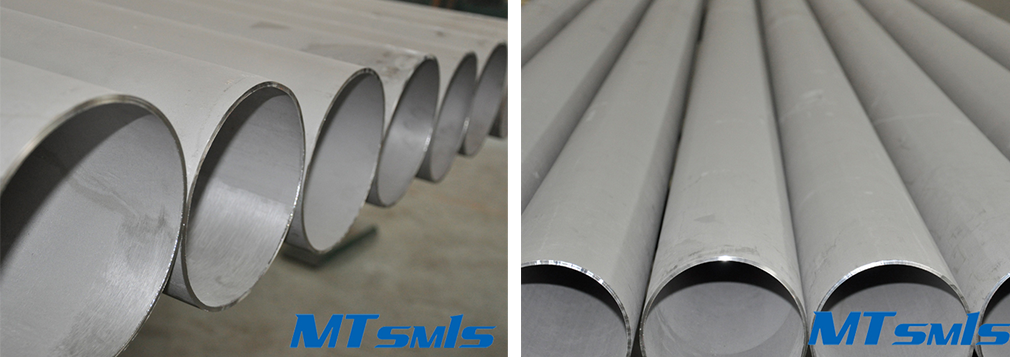

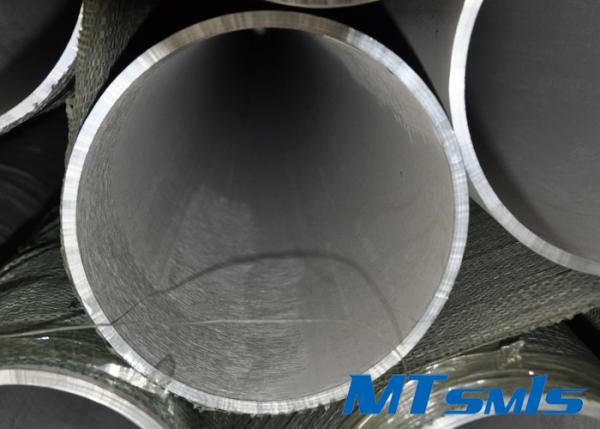

6Mo Pipe/31254 Pipe

6Mo (UNS N08926) pipes and 31254 (UNS S31254) pipes are both super austenitic stainless steels with extremely high corrosion resistance. They contain high proportions of molybdenum (Mo), chromium (Cr) and nitrogen (N), and can provide excellent resistance to pitting, crevice corrosion and stress corrosion cracking in high chloride ion concentrations and strong oxidizing media. Both materials have good mechanical strength and excellent welding properties, suitable for long-term use in extreme environments.

In terms of application, 6Mo and 31254 pipes are widely used in marine engineering, seawater desalination, chemical equipment, pulp and paper industry and other fields that require extremely high material corrosion resistance. They are especially suitable for key parts such as heat exchangers, pressure vessels, condensers, and piping systems, which can effectively extend the service life of equipment and reduce maintenance costs. Both are often regarded as economical alternatives to nickel-based alloys and titanium.

Parameter Table:

Specifications of 6Mo Pipe/31254 Pipe

| |

Item | Details |

Standard | ASTM A312 / ASTM A358 / ASTM B677 |

Grade | 6Mo / UNS S31254 / 254SMO |

Outside Diameter | 8mm – 711mm |

Wall Thickness | 1mm – 50mm |

Length | ≤ 20m |

Inspection | Appearance / Dimensional test / PMI / UT / ET / HT / Mechanical & Chemical tests |

Certificates | ISO / PED / AD2000 / TS |

Package | End protection / Woven bags / Wooden cases |

Factory advantages and features:

Huxin Pipe, a seamless steel pipe manufacturer owned by MTSCO Investments, is trusted for its 36 years of experience in pipe manufacturing. The factory not only supplies regular sized pipes, but can also provide extended pipe lengths of 18 and 25 metres to meet the needs of different customers.

Huxin Pipe's factory is well-equipped, including cold rolling mill, annealing furnace, pickling tank, ultrasonic eddy current machine, and physical and chemical laboratories, etc. These advanced equipments provide a strong guarantee for the manufacturing of seamless steel pipes.

In terms of quality control, HUXIN PIPE has a set of perfect quality control process, and professional MTSCO QC inspectors are involved in the whole process of control before, during and after production, which provides customers with more reliable product quality guarantee.

In addition, Huxin Pipe's products have passed ISO, PED and AD2000 certifications, which proves its strength and reputation in quality.

Introduction to Quality Control Inspection Methods:

Raw Material Quality Control

MTSCO's pipe raw materials are sourced from reputable steel mills like Baosteel and Tsingshan. To guarantee quality, each batch of raw materials must come with a warranty and PMI (Positive Material Identification) test report. We conduct stringent PMI and other inspections to verify that the materials meet the specified requirements.

In-Production Process Control

MTSCO's seamless pipe production processes encompass cold rolling, cold drawing, annealing, pickling, surface treatment, and more. Each stage utilizes advanced production equipment, overseen by our team of experienced engineers and technicians. Every step is meticulously supervised and documented photographically for archival purposes. We employ process cards to ensure the accuracy and traceability of the entire production process.

Quality Control Prior to Shipment

MTSCO boasts a dedicated QC (Quality Control) team that meticulously inspects and tests each product, covering aspects such as appearance, PMI, dimensions, quantity, and more. We also conduct mechanical testing, hardness testing, ultrasonic testing, eddy current testing, hydraulic testing, and other specialized evaluations. Additionally, we welcome third-party testing from reputable organizations like SGS, TUV, and BV. Prior to shipment, we employ appropriate and secure packaging methods, including container reinforcement, to safeguard the goods against damage during transportation.

Customer Cases:

Project/Facility name | SOREK II DESALINATION PLANT

|

Country | Middle East |

EPC | IDE Technogles/BUTTING

|

Material | S32750, S31254, SS316L

|

Products | PIPE/FITTING/PLATE

|

Qty(KGS) | 70000 |

Year | 2024 |

Packing of 6Mo Pipe/31254 Pipe:

Product | Packing |

LCL PIPE | Plywood crate + protective pipe caps on both ends |

FCL PIPE | Woven bag + protective pipe caps on both ends |

LCL/FCL TUBE | Plywood crate + individual plastic bag wrapping + end caps on both sides |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: : Seamless Pipe

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語