Technical analysis of stainless steel heat exchange coiled tubing--high-efficiency heat exchange solutions

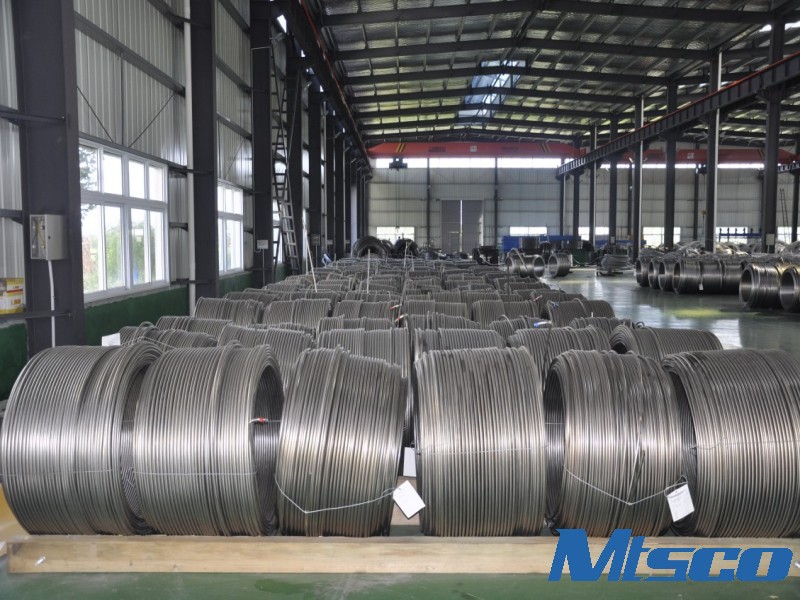

Coiled tubing are a type of pipe widely used in various industrial heat exchange equipment. Due to their unique structural advantages, they are widely used in petrochemical, geothermal energy, refrigeration, shipbuilding, power and other industries. Compared with traditional straight tube structures, coiled tubing have higher heat exchange efficiency, more compact installation forms, and stronger pressure resistance and corrosion resistance.

The structure of the coiled tubing can be U-shaped, spiral, multi-layer coiled tubing, etc. Its characteristics of multiple bends and multiple contact surfaces make the fluid stay longer in the tube and the flow path more complex. It can greatly improving the heat exchange efficiency. Especially in places where space is limited or efficiency requirements are extremely high, coiled tubing are an ideal choice.

In energy engineering, such as geothermal systems or boiler equipment, coiled tubing can be used as preheaters or condensers to effectively improve energy utilization. In refrigeration systems, spiral coiled tubing can quickly achieve heat exchange and reduce energy consumption. In the field of shipbuilding and marine engineering, coiled tubing can also adapt to complex environments such as high salt spray and high humidity to maintain stable operation. Although coiled tubings are mostly hidden inside the system, their contribution to system efficiency and operational safety cannot be ignored. Because of its important position in the heat exchange system, the manufacturing quality, material selection and process of stainless steel coiled tubing have also become crucial.

As a stainless steel pipeline solution provider, MTSCO has focused on coiled tubing products in the fields of international heat exchangers, geothermal, shipbuilding, oil and gas for more than ten years. Supports a variety of standards and material customization, covering 304, 316, 2205, 625/825, etc., to meet the requirements of high pressure, high temperature, corrosion resistance and other working conditions. If you are interested in any product, please leave a message or send an inquiry, and we will provide you with a detailed reply as soon as possible.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語