Coiled Tubing, Control Line

Leading Control Line Supplier, Serving the global top 10 oil service companies.

Specialized tubing known as control line tubing is utilized for transmitting hydraulic fluids and control signals across various industries. This precisely constructed tubing guarantees precise communication and control among different system components, particularly in challenging or remote environments.

Control line tubing is often found in applications such as oil and gas wells, where it helps regulate wellbore pressure, monitor temperature, and manage fluid injection. It's also crucial in aerospace and automotive sectors for hydraulic and pneumatic systems.

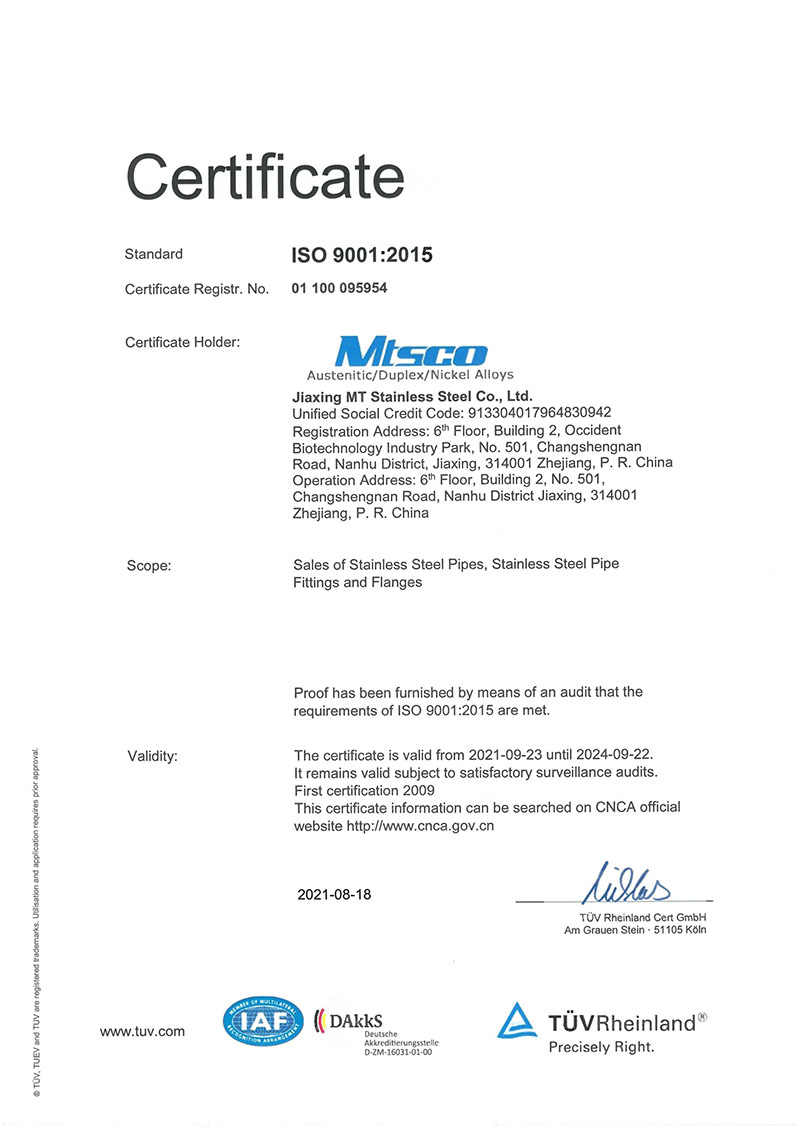

MTSCO has been providing coiled tubing for the international geothermal, heat exchanger, shipbuilding, oil and gas industries for over a decade. We can produce according to various international standards, with main materials including 304/316/2205/2507/alloy 625/825, etc.

In recent years, we have continuously made breakthroughs in the fields of coiled tubing, downhole control line, and chemical injection line. We mainly produce welded/seamless coiled tubing, capillary tubes, control line tubing, multi core tubing and cables.

MTSCO welded coiled tubing can be up to 33,000fts/coil. And it can pass the max hydraulic pressure of 100MPA. Our seamless coiled tubing can be up to 120kgs/ coil. We can provide various encapsulated plastic material, such as PP,TPV,TPU,PVC,PVDF...

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteSpecifications of Control Line Tubing

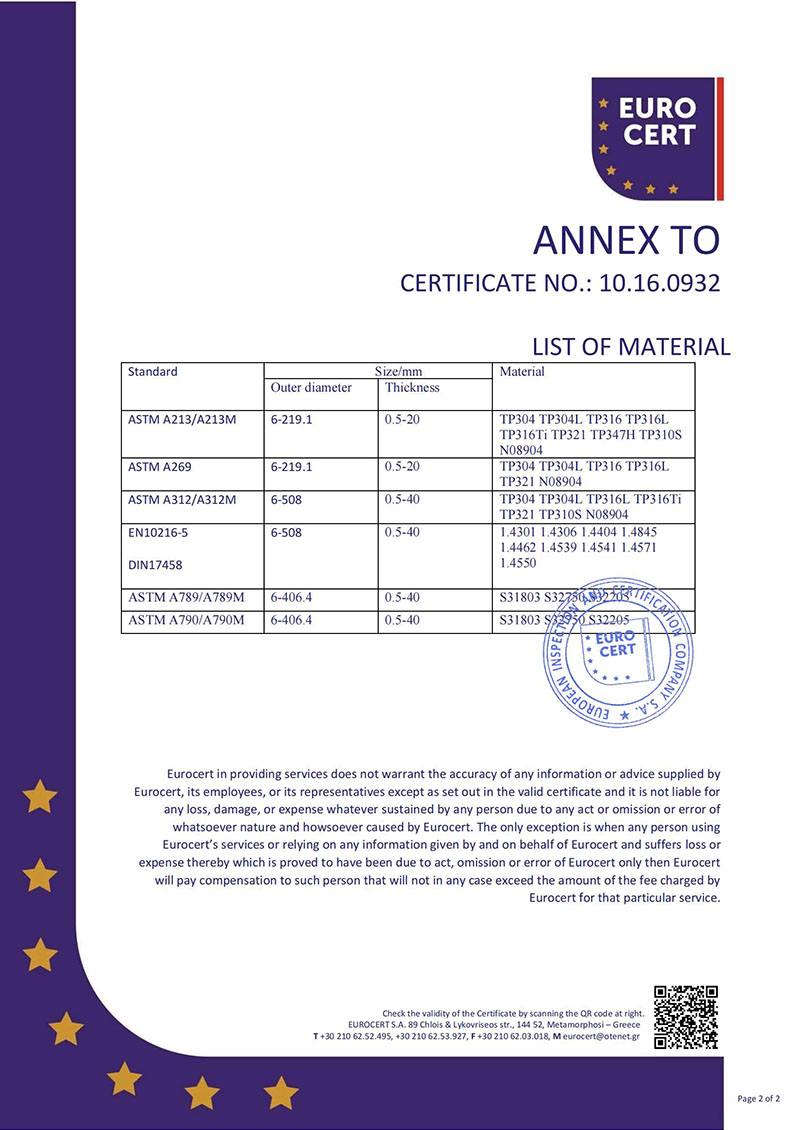

Standard |

ASTM A269 |

Materials |

Austenitic: 304/L, 316/L, 316Ti... |

Specifications |

||||||||

|

Products

Quality Control of MTSCO Coiled Tubing

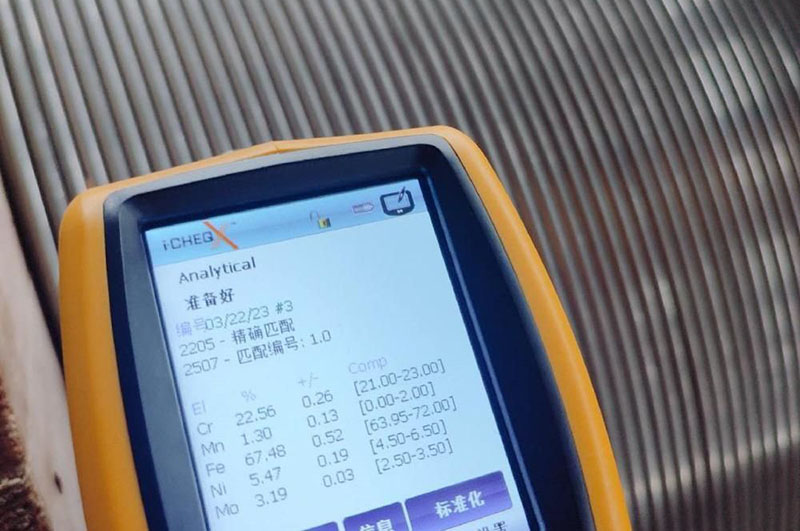

1. Quality Control of Raw Materials

Our raw materials come from large factories such as Baosteel, TSINGSHAN, WALSIN, POSCO,JISCO, ANSTEEL, ATI...Each batch of raw materials requires MTC and PMI. After the raw materials arrive, we conduct PMI and other inspections again to ensure that they meet the requirements.

2. Process Control During Production

The mainly production process includes welding, cold drawing, bright annealing and plastic wrapping.

Each process is supervised by experienced engineers and technicians. Each link is supervised by professional qc inspectors and photographed for archiving. The entire process uses process cards to ensure accuracy and traceability.

3. Quality Control Before Shipment

MTSCO has professional QC team to conduct a series of inspections and experiments on the tubes, including routine appearance, PMI, size, quantity, and other inspections. At the same time, we also conducts mechanical testing, hardness testing, airtightness,UT, ET, HT and other tests. Among them, welded coiled tubing can pass the max hydraulic pressure of 100MPA.

In addition, we also accept third-party inspection, such as SGS, TUV, and BV.

Package

As a factory complex consisting of multiple factories. MTSCO has many years of experience inpackaging and loading. The packaging are generally plastic reel, wooden reel, solid woodenreel, iron reel, iron and wooden reel, wooden boxes aand so on. Reinforcement with woodenstrips and ropes when loading cabinets.

All inspection results and loading process will be documented with photos for your traceability requirements.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語