ASTM A249 TP304/304L/TP316/316L/316Ti Chemical Injection Line

SSSSLCT09

Material: 304, 1.4301, X5CrNi18-10; 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435; 316Ti, S31615, 1.4571, S31635;

Get Quote

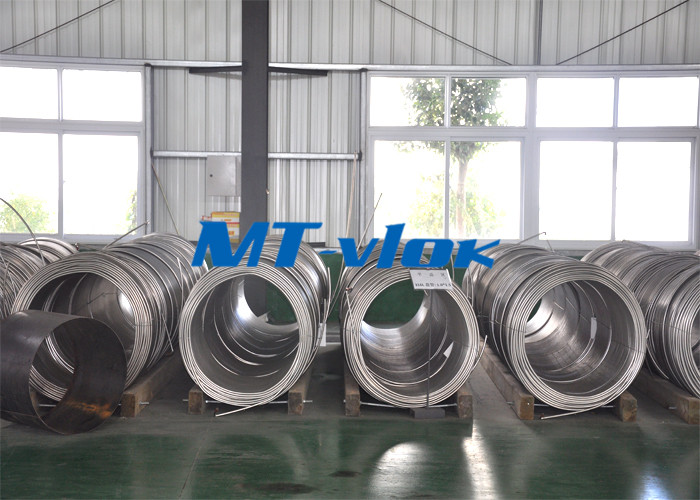

4.76mm 316L / 1.4404 Stainless Steel Welded Super Long Coiled Tube In Oil And Gas

Chemical Composition :

| Material | ASTM A269 Chemical Composition % Max | ||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

| TP304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^. | ^ |

| TP304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

| TP316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP316L | 0.035 D | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

| TP347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ |

Material Grade :

| American Standard | TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L Etc |

| European Standard | 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 Etc |

| German Standard | X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 , X5CrNi17-12-3 , X2CrNiMo18-14-3 , X6CrNiTi18-10 , X6CrNiTb18-10 Etc |

ASTM A213 / A213M Chemical Composition :

| Elements | 304L(wt%) S30403 | 304(wt%) S30400 | 316L (wt%) S31603 | 316 (wt%) S31600 |

| (C) Carbon, max | 0.035 | 0.08 | 0.035 | 0.08 |

| (Mn) Manganese, max | 2 | 2 | 2 | 2 |

| (P) Phosphorus, max | 0.045 | 0.045 | 0.045 | 0.045 |

| (S) Sulfur, max | 0.03 | 0.03 | 0.03 | 0.03 |

| (Si) Silicon, max | 1 | 1 | 1 | 1 |

| (Ni) Nickel | 8.0 - 12.0 | 8.0 - 11.0 | 10.0 - 14.0 | 10.0 - 14.0 |

| (Cr) Chromium | 18.0 - 20.0 | 18.0 - 20.0 | 16.0 - 18.0 | 16.0 - 18.0 |

| (Mo) Molybdenum | N/A | N/A | 2.0 - 3.0 | 2.0 - 3.0 |

| (Fe) Iron | Bal. | Bal. | Bal. | Bal. |

| (Cu) Copper | N/A | N/A | N/A | N/A |

| (N) Nitrogen | N/A | N/A | N/A | N/A |

| Size | OD : 4.76 - 25.4mm |

| WT : 0.71 - 2.11mm | |

| Length : >1000Meters | |

| 4.76 * 0.71mm / 4.76 * 0.89mm / 4.76 * 1.24mm | |

| 6 * 1mm / 6 * 1.5mm | |

| 6.35 * 0.71mm / 6.35 * 0.89mm / 6.35 * 1.24mm / 6.35 * 1.65mm | |

| 7.94 * 0.71mm / 7.94 * 0.89mm / 7.94 * 1.24mm / 7.94 * 1.65mm | |

| 9.53 * 0.71mm / 9.53 * 0.89mm / 9.53 * 1.24mm / 9.43 * 1.65mm | |

| 10 * 1mm / 10 * 1.5mm | |

| 12 * 1mm / 12 * 1.5mm / 12 * 2mm | |

| 12.7 * 0.71mm / 12.7 * 0.89mm / 12.7 * 1.24mm / 12.7 * 1.65mm / 12.7 * 2.11mm | |

| 14 * 1mm / 14 * 1.5mm / 14 * 2mm | |

| 15.88 * 0.89mm / 15.88 * 1.24mm / 15.88 * 1.65mm / 15.88 * 2.11mm | |

| 16 * 1mm / 16 * 1.5mm / 16 * 2mm | |

| 19.05 * 0.89mm / 19.05 * 1.24mm / 19.05 * 1.65mm / 19.05 * 2.11mm | |

25.4 * 0.89mm / 25.4 * 1.24mm / 25.4 * 1.65mm / 25.4 * 2.11mm |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Welded / Seamless Coiled Tubing

ASTM A269 / ASME SA269 1 / 4 Inch Stainless Steel Welded Super Long Coiled Tube

Where the coiled tubing used ? 1 . Control tubing in oil and gas well 2 . Instrument tubing 3 . Chemicl injection tubing line 4 . Pre-insulated tubing 5 . Electric heating or steam heating tubing line 6 . Hater tubing line 1 . Our company has been dedicated to producing seamless coiled......

3 / 8 Inch 17.1mm TP321 / 321H Stainless Steel Seamless Coiled Tubing With Cold Rolled

1 . Our company has been dedicated to producing seamless coiled tubing since 2014 , owning complete producing technology and abundant managing experience . 2 . The raw material such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Yongxing etc . 3 ......

Stainless Steel Spiral Wound Tube 304L/ 316L Cold Rolled For Oil Drilling

What is Spiral Wound Tube? Spiral Wound Tube (SWT) is a type of pipe construction made by alternately winding metal strips with packing. This type of pipe construction is often used to make sealing elements such as packing gaskets and sealing washers to ensure the tightness of pipes and vessels....

ASTM A789 S32750 / 2507 super duplex steel coil tubing oil and gas

2507 Super Duplex is a high alloy duplex stainless steel with a PRE (pitting resistance equivalent) value of 42.5 minimum. The grade is characterized by very good chloride corrosion resistance, combined with very high mechanical strength. It is particularly suited for use in aggressive environments ......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語