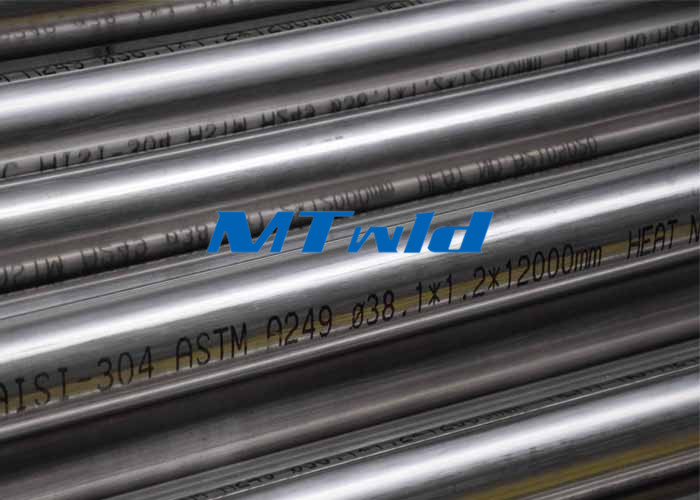

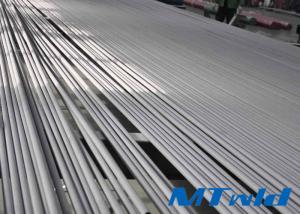

ASTM A249 304L / 316L Stainless Steel Welded Tube For Heat Exchanger

SSHEWT01

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435;

Get Quote

ASTM A249 304L / 316L Stainless Steel Welded Tube For Heat Exchanger

ASTM A249 Standard :

| Size OD | Nominal Wall | Outside Diameter | Length | Wall |

| 1/2" (12.7) | 0.065" (1.65)/0.049" (1.25) | +/-0.005 (0.13) | +1/8" (3.18) - 0 | +/-10.0% |

| 3/4" (19.1) | 0.065" (1.65)/0.049" (1.25) | +/-0.005 (0.13) | +1/8" (3.18) - 0 | +/-10.0% |

| 1" (25.4) | 0.065" (1.65)/0.049" (1.25) | +/-0.005 (0.13) | +1/8" (3.18) - 0 | +/-10.0% |

| 1-1/2" (38.1) | 0.065" (1.65)/0.049" (1.25) | +/-0.008" (0.20) | +1/8" (3.18) - 0 | +/-10.0% |

| 2" (50.8) | 0.065" (1.65)/0.049" (1.25) | +/-0.008" (0.20) | +1/8" (3.18) - 0 | +/-10.0% |

| 2-1/2" (63.5) | 0.065" (1.65) | +/-0.010" (0.25) | +1/8" (3.18) - 0 | +/-10.0% |

| 3" (76.2) | 0.065" (1.65) | +/-0.010" (0.25) | +1/8" (3.18) - 0 | +/-10.0% |

| 4" (101.6) | 0.083" (2.11) | +/-0.015" (0.38) | +1/8" (3.18) - 0 | +/-10.0% |

| 6" (152.4) | 0.083" (2.11) | +/-0.030" (0.76) | +1" (25.4) - 0 | +/-10.0% |

| 6" (152.4) | 0.109" (2.77) | +/-0.030" (0.76) | +1" (25.4) - 0 | +/-10.0% |

| 8" (203.2) | 0.109" (2.77) | +0.061" (1.55)/-0.031" (0.79) | +1" (25.4) - 0 | +/-10.0% |

| Material Grade | TP304, TP304L, TP304H, TP316, TP316L, TP316Ti, TP309S, TP310S, TP321, TP321H, TP347, TP347H, etc |

| Outer Diameter | 5.80mm-2032mm (0.23" to 80") |

| Wall Thickness | 0.25mm-28mm (0.01" to 1.125") |

| Length | Normally fixed length 6m, can as per customer’s requirement |

| Standard | ASTM A312; ASTM A269; ASTM A789; ASTM A790 ect. |

| Process Method | ERW, EFW etc |

Application :

a) For fluid and gas transport

b) Structure and machining

c) Heat exchanger pipes etc

| Stanard Wire Gauge ( Fomerly Imperial Wire Gauge ) SWG | |||||

| SWG | Wall Thickness | SWG | Wall Thickness | ||

| 0 | 0.324 | 8.23 | 21 | 0.032 | 0.81 |

| 1 | 0.3 | 7.62 | 22 | 0.028 | 0.71 |

| 2 | 0.276 | 7.01 | 23 | 0.024 | 0.61 |

| 3 | 0.252 | 6.4 | 24 | 0.022 | 0.56 |

| 4 | 0.232 | 5.89 | 25 | 0.02 | 0.51 |

| 5 | 0.212 | 5.38 | 26 | 0.018 | 0.46 |

| 6 | 0.192 | 4.88 | 27 | 0.0164 | 0.42 |

| 7 | 0.176 | 4.47 | 28 | 0.0148 | 0.38 |

| 8 | 0.16 | 4.06 | 29 | 0.0136 | 0.35 |

| 9 | 0.144 | 3.66 | 30 | 0.0124 | 0.31 |

| 10 | 0.128 | 3.25 | 31 | 0.0116 | 0.29 |

| 11 | 0.116 | 2.95 | 32 | 0.0108 | 0.27 |

| 12 | 0.104 | 2.64 | 33 | 0.01 | 0.25 |

| 13 | 0.092 | 2.34 | 34 | 0.0092 | 0.23 |

| 14 | 0.08 | 2.03 | 35 | 0.0084 | 0.21 |

| 15 | 0.072 | 1.83 | 36 | 0.0076 | 0.19 |

| 16 | 0.064 | 1.63 | 37 | 0.0068 | 0.17 |

| 17 | 0.056 | 1.42 | 38 | 0.006 | 0.15 |

| 18 | 0.048 | 1.22 | 39 | 0.0052 | 0.13 |

| 19 | 0.04 | 1.02 | 40 | 0.0048 | 0.12 |

| 20 | 0.036 | 0.91 |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Welded Pipe: Welded Tube

1 / 2 Inch Duplex Steel Small Diameter Welded Tube

1.Material Grade S32205, S31803, S32304, S32750, F51, F53, 2205, 2507 etc 2.Outer Diameter3.18mm to 101.6mm 3.Wall Thickness 0.5mm to 20mm 4.Length Normally fixed length 6m, can as per customer’s requirement 5.Standard ASTM A789; ASTM A790; EN 10216-5 etc. 6.Process Method Cold Drawn or Cold R......

TP309s / 310s Stainless Steel U Bend Heat Exchanger Tube, ASTM A269 Welded Tube For Boiler

Our heat exchanger tube with pickling and annealing surface is very popular in boilers and heat exchangers industry , water heater industry , air-conditioning industry etc . This kind of seamless tubes are have a very important position in our all products . Grade:TP 304; TP304H; TP304L; TP316; ......

ASTM A249 TP304 / S30400 Stainless Steel ERW Straight Tube For Heat Exchanger

Our heat exchanger tube with pickling and annealing surface is very popular in boilers and heat exchangers industry , water heater industry , air-conditioning industry etc . This kind of seamless tubes are have a very important position in our all products . Application a) For fluid & gas......

6.35mm ASTM A269 Stainless Steel Bright Annealed Welded Tubing in Transportation

Stainless steel seamless bright annealed tube's final surface is polished and bright annealed. And the polished grade is includes 180#, 320#, 400#, 600#, 800#. According to standard very strictly, tubes which produced by us always have correct OD and WT tolerance. And they are very suitable for chro......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語