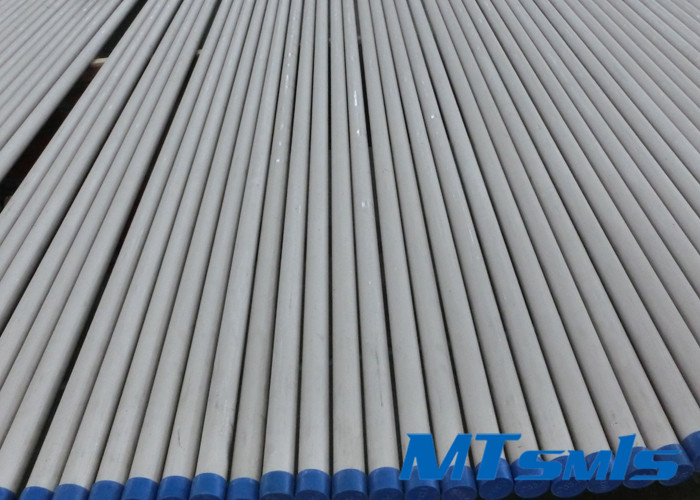

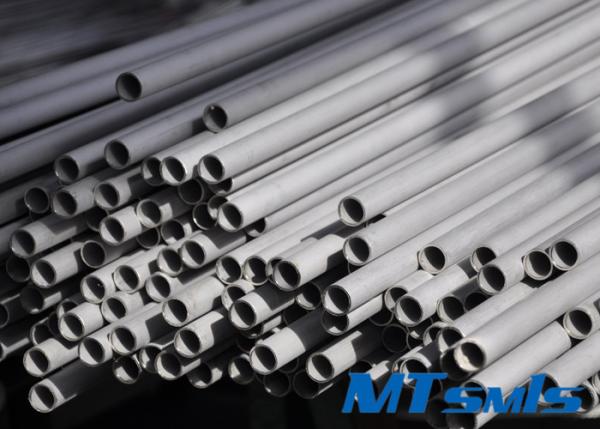

ASTM A789 Stainless Steel Duplex Tube With Good Impact Toughness

SSDST20

Price: From $5500-8000USD/TON

Material: S32205, S31803, 1.4462;

Get Quote

ASTM A789 1.4462 / S32205 Stainless Steel Duplex Tube With Good Impact Toughness

Material Grade: S32205 , S31803 , S32304 , S32750, F51 , F53 , 2205 , 2507 etc

Outer Diameter: 3.18mm - 101.6mm

Wall Thickness: 0.5mm - 20mm

Length: as per customer's requirement

Standard: ASTM A789 ; ASTM A790 ; EN 10216-5 etc.

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

| Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) |

| Package | Iron case; woven bag or as per customer’s requirement |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

| Test | NTD(Ultrasonic test, Eddy Current test); |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test); | |

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature); | |

| Chemical Analysis(Photoelectric Emission Spectroscopic) | |

| Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Features :

1 . Outstanding resistance to pitting and crevice corrosion in seawater and other chloride containing environments, with critical pitting temperature exceeding 50°C

2 . Excellent ductility and impact strength at both ambient and sub-zero temperatures

3 . High resistance to abrasion, erosion and cavitation erosion

4 . Excellent resistance to stress corrosion cracking in chloride containing environments

5 . ASME approval for pressure vessel application

Super duplex stainless such as duplex is a mixed microstructure of austenite and ferrite which has improved strength over ferritic and austenitic steel grades . The main difference is super duplex has a higher molybdenum and chromium content which gives the material greater corrosion resistance . Super duplex has the same benefits as its counterpart - it has lower production costs when compared with similar ferritic and austenitic grades and due to the materials increased tensile and yield strength , in many cases this gives the purchaser the welcomed option of purchasing smaller thicknesses without the need to compromise on quality and performance .

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

2205 Material Duplex Steel Tube Hydraulic Test With Pickling Surface

S32205 duplex stainless steel tube combines excellent corrosion resistance and high strength, and can effectively resist pitting, crevice corrosion and stress corrosion cracking caused by chloride ions....

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語